Currency

CHECK OUT " READY TO SHIP" -- EQUIPMENT INVENTORY -- BY CLICKING THE RESOURCES TAB

LOCATED ON THE BLACK MAIN NAVIGATION BAR BELOW.

LOCATED ON THE BLACK MAIN NAVIGATION BAR BELOW.

Tunnels

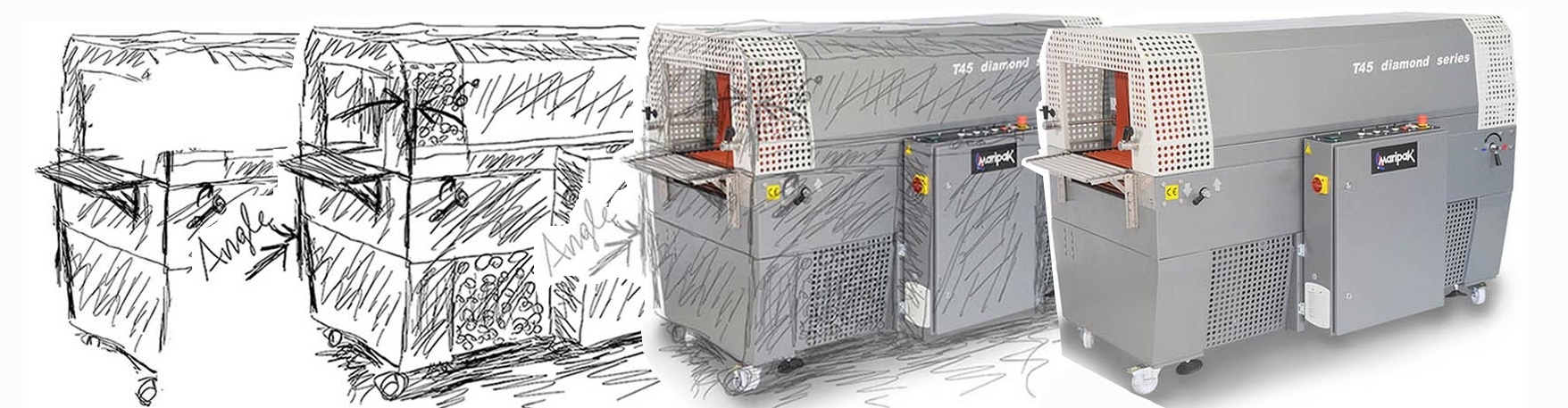

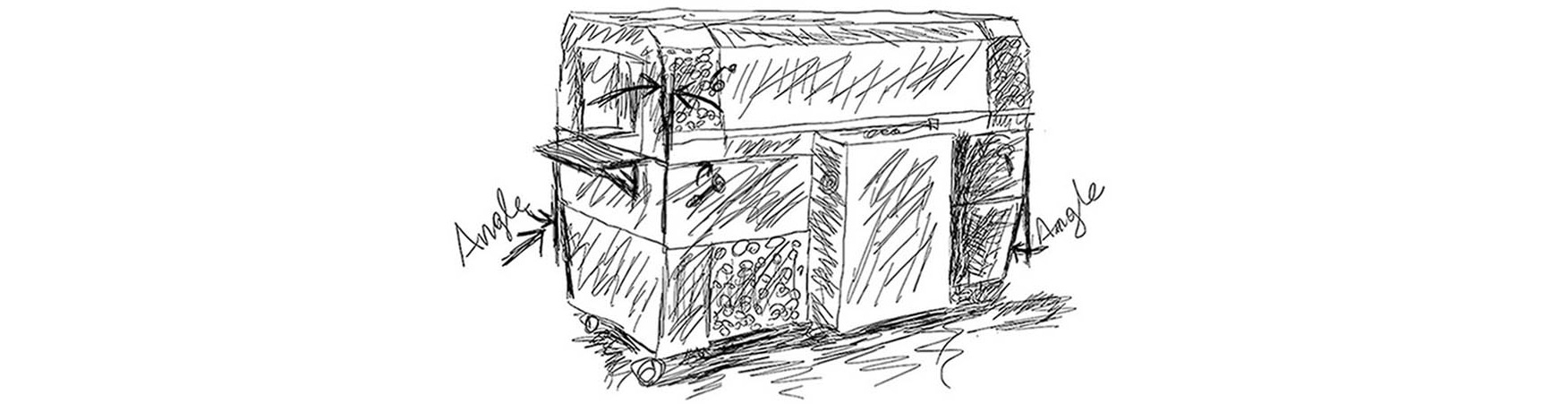

The Evolution of Perfection

developed with perfection of performance only in mind.

Explore the Maripak Line of Heat Tunnels

Trusted by 12,000 plus customers globally

and 30 plus international service distributors

Mini & Midi Series Preview

Designed for Performance

Pure Packaging Intelligence

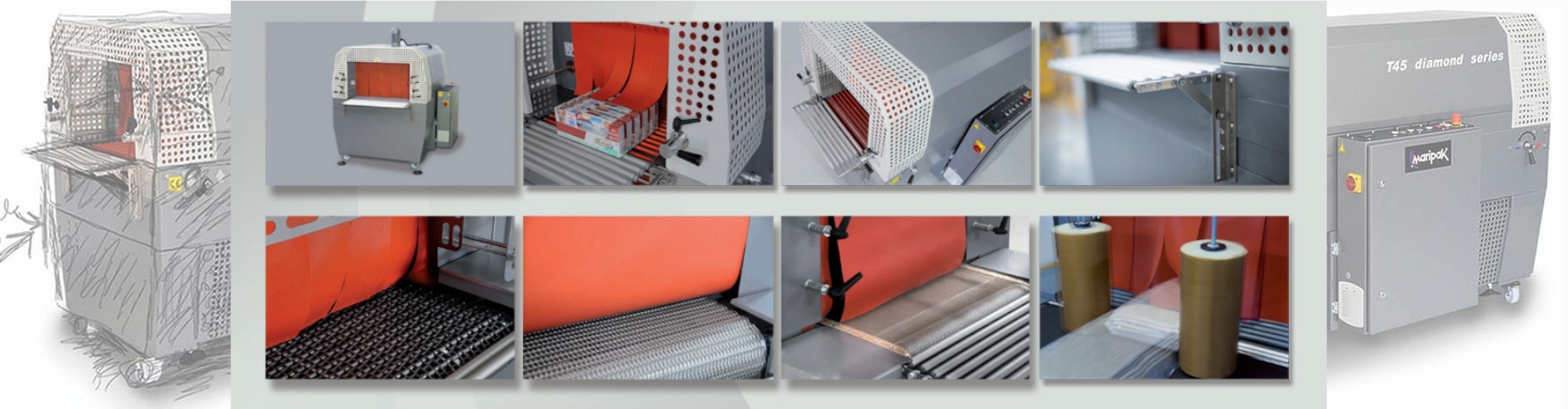

Diamond Series Preview

Designed for Performance

Pure Packaging Intelligence