Maripak’s entry into the inline PE sealers arena are designed for fully-automatic PE sealing applications where higher speeds and rugged reliability are prime considerations in a medium to large sized user. Built to the same exacting high standards as all of their higher end wrappers, these versatile units are capable of wrapping many pieces. System estimates are 20 cycles/minute and higer in the servo version depending on size and film type when combined with the proper infeed.

The MULTIMAC "D" 100 is easy to use and rugged enough for constant and consistent operation on a daily basis while taking up minimal space.

LOCATED ON THE BLACK MAIN NAVIGATION BAR BELOW.

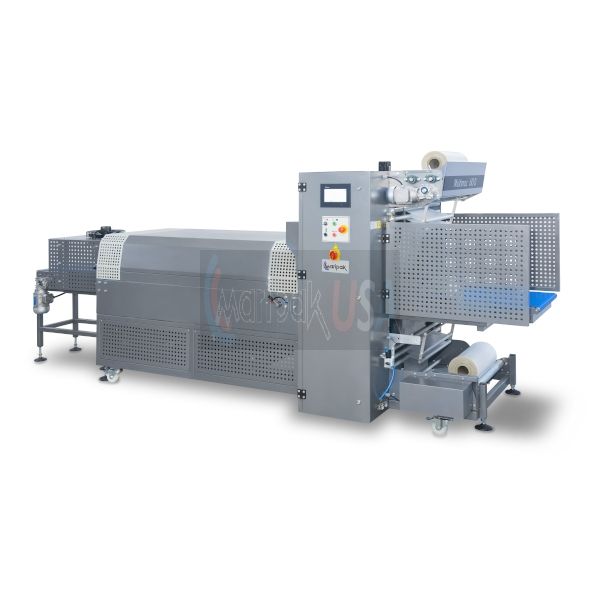

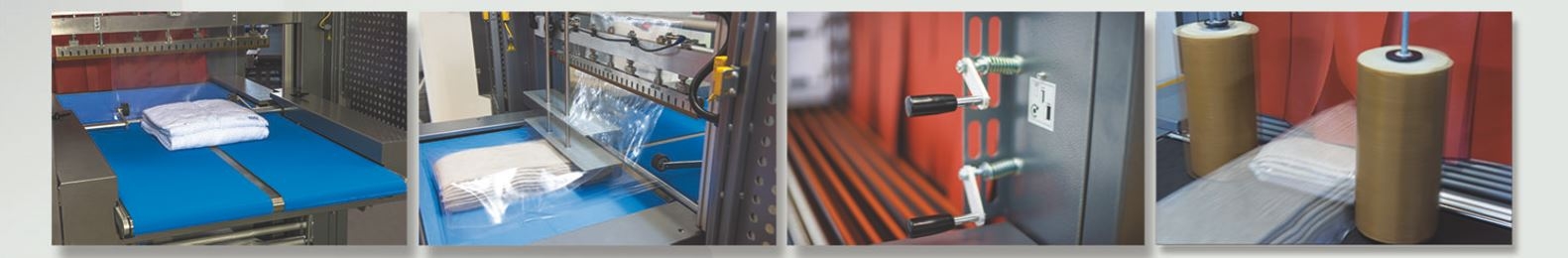

PE Sealer - Multimac "D" 100

The Maripak - MULTIMAC "D" Series - Fully-Automatic - PE Sealer is a must have quality built machine. Maripak’s entry into the PE sealer and bundler arena are designed for fully-automatic sealing applications where medium to high speed and rugged reliability are prime considerations.

Built to the same exacting high standards as all of their higher end wrappers, these versatile units are heavy duty units that run with percision while being capable of wrapping many pieces.

System estimates are approx 20 cycles/minute and higher in the servo version depending on size and film type when combined with the proper infeed. .

The MULTIMAC "D" 100 is easy to use and rugged enough for constant and consistent operation when extremely fast and accurate product packaging is a must.

See below for specific specification details and information. Configure and build your own machine with options by request.

Custom notifications:

This model is built to order... Materials are in stock to manufacturer and build this machine. Please use the "Get A Quote" button for an instant personalized e-quote.MULTIMAC "D" 100 - AUTOMATIC - PE SEALER - MODEL # MMACD100

They come standard with premium features not available on most competitive models in this price range including low-mount film cradle, easy operation controls, touchscreen library to easily recall package setups, and automatic dwell time compensator.

The Maripak’s exclusive Hands on Design make these units the most user-friendly side sealer packaging unit on the market today. World-Wide approved brands for all mechanical and electrical components make the MULTIMAC "D" 100 as popular with maintenance staffs as with operators.

When your application calls for an automatic PE sealer wrapper capable of fully-automatic operation, Maripak’s MULTIMAC "D" Series offers the lowest total-cost-in-operation available today with the most advanced and evolved technologies.

All PARTS are stocked and available for immediate shipment. All technical support, service, and machine and equipment parts are fully supported by our dedicated technical Service Support and Parts fulfillment location in the Greater Tampa FL area.

* Additional MULTIMAC "D" Series models are available for various size products, see our other models as well in this MULTIMAC "D" Equipment Series.

Technical Specifications

- Seal Bar Opening: 16" - (400mm)

- Maximum Conv. Speed: 65 ft / minute - (20 mt / minute)

- option to be adjustable - Maximum Cycles: 20 cycles / minute -

- ( 35 cycles / minute

- in servo version) - Maximum Roll Diameter: 14" - (350mm) - adjustable

- Working Height: 38" - (960mm)

- Compressed Air Supply: Yes - air required - 6 bar

- Film Types: PE- Polyethylene

- Film Thickness (min / max): 1 mil - 3 mil / 30 to 80 micron

- Color: Customized - Mixed Gray

RAL7015 + RAL7010 - Cross Sealer Length: 41" - (1050mm)

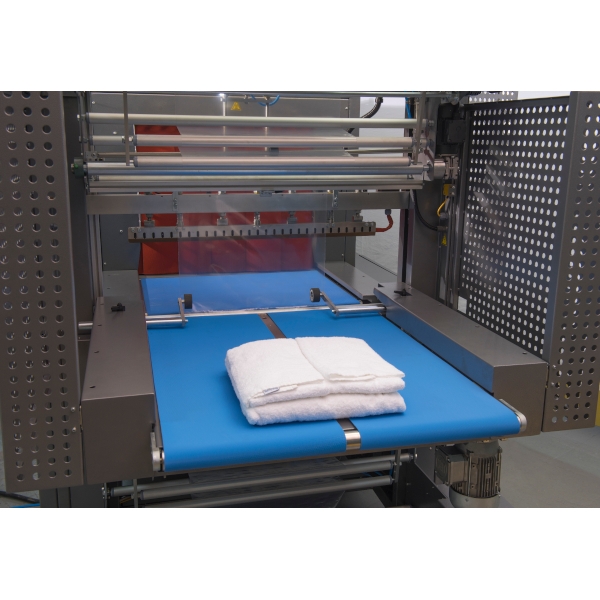

- Conveyor Belt Width: 39" - (1000mm)

- Maximum Film Width: 39" - (1000mm)

- Installed Power: 220 V - 96 Amp - 3 Phase

** 480 V - 3 Phase Option for MTO - Consumption (Max / Average): 32 kW / 17 kW

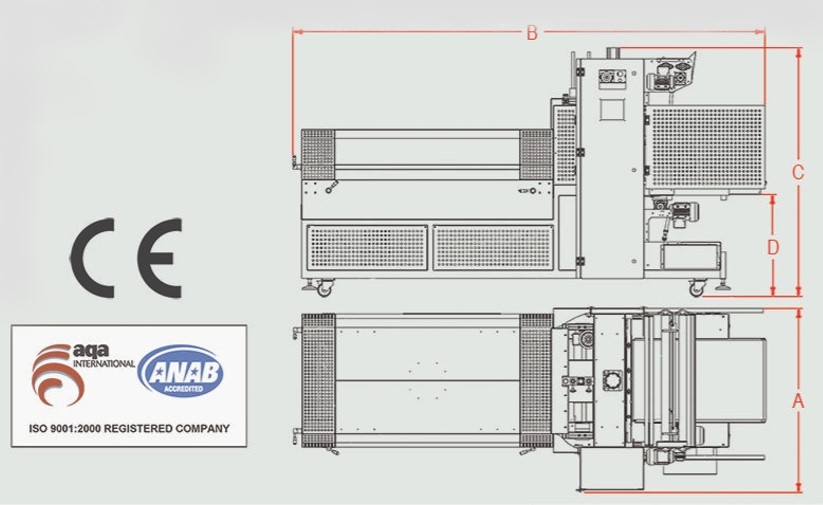

- Dimensions (AxBxC): 63" x 138" x 89"

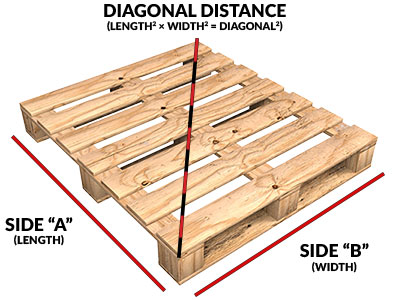

- (1600 x 3500 x 2250mm) - Palletized Size (AxBxC) :71 x 140 x 96"

- (1800 x 3350 x 2450mm) - Weight (Net / Gross): 2601 lbs / 2976 lbs

- (1180 kg / 1350 kg)

* For DIN A4 form and MULTIMAC "D" Series real working speed depends on the product dimensions and film type.

** Optional Power / Electrical option upgrade to 480 V - 3 Phase for an upcharge with MTO ( made to order ) equipment.

Advantages:

- Compact design of PE wrapper and heat tunnel combo on a single chassis

- Customized design and strengthened mechanical properties for high products

- Easy to integrate due to casters with brakes into any production line directly

- High speed automation with inline-motion packaging system

- Non-stop packaging operation for faster production speeds

- Recordable and re-callable package parameter settings

- Combination unit built for reduced energy consumption

- Easy to use, compatible with health and safety standards

Features:

- Fully-automatic system with motorized inlet / discharge belt conveyors

- Automatic encoder controlled speed and length detection by sensor synchronization

- Feeding frequency control by sensor detection and PLC control

- User-friendly color touch screen operation control panel

- Excellent balancing of sealing blade on conjugated linear bearings

- Auto PE film driving motorized rollers triggered by suspension arm

- Ability to read instant or total realized capacity by counter

- Adjustable speed of tunnel conveyor for optimized heat application period

- Easy programmable format changes for different package sizes

- Heat adjustment with digital PID control

- Air circulation control by side flap handles

- Automatic post cooling mechanism for cooling down to 165 degrees F / 70 degrees C before switch off

- Additional emergency temperature control system against fire risk

- Up-to-date safety electric and mechanical measures of CE directives

Sealing:

- Teflon coated hot sealing knife embedded in visor protected top sealer

- Teflon belt covered & heat-proof silicon bed embedded bottom sealer

- PID controlled sealing temperature inserted by touch panel

- Ability to work with a wide range of film thicknesses

- Product clearance control under seal bar by auto sensor

- Film tension releasing mechanism on the cross-sealing point

Flexibility:

- Ability to utilize single layer film with accurate width

- Easily adjustable for varying product sizes and capacity requirements

- Runs with flat film which is an overall advantage

- Native, various, and new added language options on adaptable touch keyboard

- Memory Recipe property for prompt and package dimension adjustments

- Perfect sealing blade design compatible with varying thicknesses

- Warning notifications and messages for potential emergency cases

- "Navigation Control" for actual throughput and estimated packs/time units

Optional:

- Right To Left - Standard Machine Flow Orientation

- Change of Flow Orientation - to Left To Right - Option - Add 5% Upcharge

- Printed film applicability by marker detection sensor and programing

- Fully controlled easy film drive mechanism for both top and bottom PE rolls

- Repositioning of top and bottom PE film roll nests to waist level

- Spare roll nest and manual film splicing unit

- Ability to control additional conveyors by inverters

- Ability to stabilize and pressurize unsteady products by top-pressure cylinder

- Enhanced pressure and position control of vertical sealer by SERVO motor

- Linking conveyor: Non-rigid, wavy-based or short products ( L< 6 inches / 15 cm )

- Synchronized sealer and tunnel movement ( L< 23 inches / 60 cm )

- Ironing side-rollers at the exit of heat tunnel

Quality:

- ISO9001 quality standards with the relevant norm's confirmation

- CE certifications, complies with the latest CE directives

- World-wide approved brands for all mechanical and electrical components

- 3 year warranty for non-wearable parts against manufacturing defects or faults

- Warranty extendable by 1 year increments for additional cost

- Wearable parts are not included in warranty terms

- 1 set of wear parts is provided along with the machine

- 5 year spare part availability is provided

All Maripak machines and equipment are fabricated to the highest ISO 9001 standards and requirements

Additional Information and Resources

Price:

- The machine shown is a base unit with no options or custom additions. Price provided above is for Budgetary reasons only.

- Options and or Custom additions can be provided upon request and a custom quote will be provided by our Sales Support Group or an authorized distributor

- The Online Prices may be used for general budgetary pricing purposes only and may differ slightly and are subject to change.

- Firm pricing necessary to place any order must be confirmed with a formal quotation through the normal Maripak USA - RFQ / quote process along with the proper assignment of an authorized distributor.

- Product designations starting with " B " are ( Built-to-Order ) items which are already engineered machines or equipment, but built individually to order.

Custom notifications:

This machine will have a lead-time associated with it. One of our machine agents will advise based on the specific model #, options, and or customization of your machine. A specific lead-time will be provided at that time.

" Add to Quote " for a personalized e-quote.

| SKU | 47005 |

|---|---|

| Short Description | The Maripak - MULTIMAC "D" Series - Fully-Automatic - PE Sealer is a must have quality built machine. Maripak’s entry into the PE sealer and bundler arena are designed for fully-automatic sealing applications where medium to high speed and rugged reliability are prime considerations.  |

| Custom note | This model is built to order... Materials are in stock to manufacturer and build this machine. |

| Additional Info | This machine ships direct from the Greater Tampa Florida area and will be PLUS FREIGHT. Freight will be quoted and depend on delivery zip code.

*** Special Custom Creating will be made to ensure safe and secure shipment of the machine and will be an added to the final cost of the machine as each machine's crating is different. *** |

| Manufacturer | Maripak |

| Manufacturer's SKU | MAR-MMACD100 |

| Manufacturer's Model Number | MMACD100 |

| Manufacturer Category | Automatic PE Sealing Equipment |

| Unit of Measure | each |

REAL PACKAGING APPLICATIONS IN ACTION

MULTIMAC "D" 100 - Various Videos